Application Overview

★ Powder material coating granulation.

★ Manufacturing of spherical particles (pills).

★ Pill coating (film, enteric solubility, protective layer)

★ Slow release coating and granulation.

Equipment characteristics

★ Complete powder coating and granulation.

★ Complete the masking and coloring of powder, granules, and pills.

★ Complete the coating of powder to obtain products with extremely high sphericity.

★ Complete the coating liquefaction operation of powder, which is not easy to agglomerate or adhere.

★ The coating process for completing the powder has extremely high repeatability.

★ Complete automatic control of the liquid supply for powder coating, ensuring stable temperature in the bed without splashing.

★ Complete the automatic spraying of powder coating powder, with accurate measurement.

★ The coating of the completed powder can handle low density materials due to the compaction effect of centrifugal force.

★ Complete the coating, granulation, coating, and drying of the powder in one go.

★ The design and manufacturing comply with GMP specifications, with fast, thorough cleaning and no cross contamination.

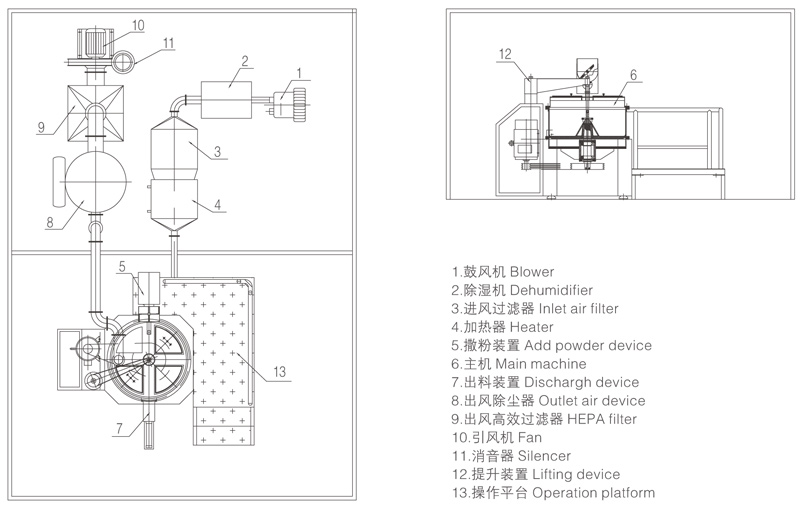

Technological process

Project specifications | Feeding amount (kg/batch) | Rotor speed (rpm) | Rotor diameter (mm) | Motor power of powder supply device (kw) | Fan power(kw) |

360 | 0.5-1.5 | 0-650 | 360 | 0.37 | 1.5 |

750 | 5-15 | 0-250 | 750 | 1.5 | 3 |

1000 | 10-25 | 0-180 | 1000 | 2.2 | 5.5 |

1300 | 15-35 | 0-150 | 1300 | 4 | 7.5 |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.